Unmanned Aerial Vehicles (“drones”) have become very popular, not just with hobbyists but also with businesses and government agencies. P&GE is looking at drones to inspect aging power infrastructure. Communities use them for surveying land. There are more and more applications for drones every day. But one of the things holding back more development is the durability of the motors and the duration of the flights. We have seen increases in flying time through motor efficiency, but operators still struggle with the durability required for a constantly operating motor.

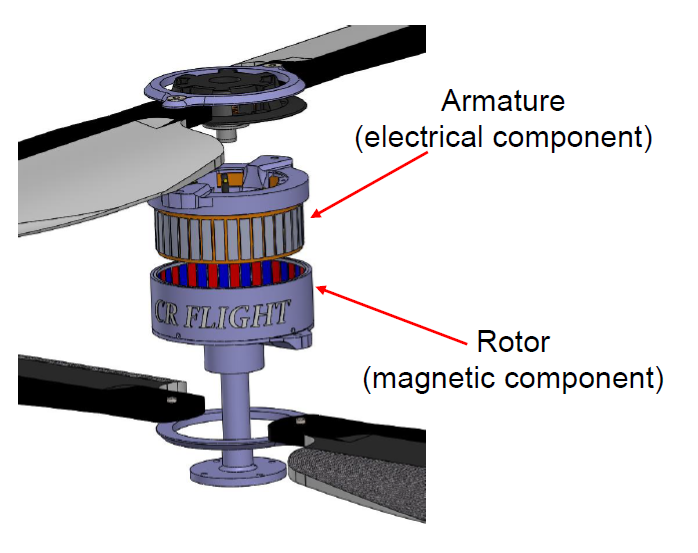

So they took on the challenge and solved it by creating a Rotary Transformer which can basically double the output power, or increase thrust or load efficiency by 30% of any motor, generator, wind turbine, HVAC, etc. The durability of the rotary transformer even surprised them. The counter-rotating parts produce several benefits. Two blades on one motor mean the blades and bearing can spin slower, also, the bearings are not stationary enabling them to be cooled better. With the rotor and armature freely spinning creating a much cooler motor and there is no torque going into the motor’s mount. All of these combine to increase durability (longer motor life) and reduce weight significantly as you can use a much smaller motor to do the job.

Enter Start-Up CR Flight, which has developed a Rotary Transformer® creating smaller, more durable motors (1000 hrs), that will enable longer flights, using a clever design for powering counter-rotating props. Founders Dr. James Richey, Jonathan Emigh, and Randy Wishart came together to work on Wishart’s idea of the motor where both the rotor and the stator rotated (making the stator into an armature). One prop is fixed to each, eliminating the need for a second motor to achieve the added lift with a second prop. Emigh saw that it would not only produce more lift but also be more durable. They validated the design with a crude prototype but realized they needed to be able to deliver power to the moving rotor, more than current slip ring manufacturers had solutions for.

CR’s biggest challenge has been in increasing the understanding of what their Rotary Transformer Technology can do with any motor. The tests for standard motors show their max power, even though they can only run at 40-50% power without burning up. With their CR Flight Rotary Transformer design, they can pull much more power from the same motor and stay cool. They rate their motors on what they can run all day long, not what their max power is. They need to demonstrate to customers directly to showcase well what they have achieved.

CR flight has developed and tested 3 motors in conjunction with the Rotary Transformer in this setup and is looking to go bigger. Once more customers understand the gains CR Flight has made in thrust efficiency, flight time, and durability, sales hopefully will soar.

ABOUT THE AUTHOR

Thomas is the Executive Director of CleanStart. Thomas has a strong background in supporting small businesses, leadership, financial management and is proficient in working with nonprofits. He has a BS in Finance and a BA in Economics from California State University, Chico. Thomas has a passion for sustainability and a commitment to supporting non-profits in the region.

Sponsors

Weintraub | Tobin, Revrnt, Moss Adams, PowerSoft.biz, Greenberg Traurig