On September 27, we held an in-person MeetUp at the California Auto Museum with three speakers talking about their work in manufacturing vehicles and improving their designs from bases here in our region.

First to speak was Jacob Panachaveettil, an engineer with Motiv Systems talking about their installation of electric drivetrains in medium duty 2-6 ton payload delivery trucks, buses and specialty vehicles. These are good applications for electric drive, because the stop-and-start driving provides opportunities for regenerative braking to extend the range. Motiv creates packaged systems to drop into the chassis of OEMs which they call EPIC (Electric Powered Intelligent Chassis). They have installed systems in over 200 trucks and buses. The current generation of their products has been demonstrated to have a range of 150 miles, which means delivery drivers can make all their deliveries in a shift without the need to get a charge along the way. Upgrades to 200 miles of range are coming. Motiv has extended its offerings to provide a charging solution and fleet maintenance service, providing an end-to-end solution for customers. They can also help customers get the point-of-sale discounts offered through the HVIP program of CARB. These vouchers are typically worth $60-80,000 for the purchase of new electric drive trucks.

Motiv was founded in 2009, in part motivated by action by CARB that same year to require companies with California to implement EV solutions to replace fossil-fueled engines by 2031. Interest in conversions has spread well beyond California, so Motiv is well-positioned as a leader in perfecting this technology. In 2012 it had a contract to convert garbage trucks to electric drive in Chicago and multiple contracts to provide electric school buses.

Motiv was founded in 2009, in part motivated by action by CARB that same year to require companies with California to implement EV solutions to replace fossil-fueled engines by 2031. Interest in conversions has spread well beyond California, so Motiv is well-positioned as a leader in perfecting this technology. In 2012 it had a contract to convert garbage trucks to electric drive in Chicago and multiple contracts to provide electric school buses.

Jacob talked about future plans to develop a Motiv line of electric trucks designed from the ground up to make maximum use of the benefits of the drive train, and also plans to look ahead to the big Class 7 and 8 long-haul trucks. But he also noted a need to focus on scale economies for standard products to get to lead a push for less costly conversions.

Motiv is a private company and according to Crunchbase has 101-250 employees. Most of those are in its factory in Hayward for now, but Motiv opened a fleet service center in Stockton and is considering its expansion options. Earlier this year it raised $30 million in a C round.

Chris Nitta, and Associate Professor at UC Davis, talked about the pioneering work done by Prof. Andy Frank on hybrid electric drives and several other innovations now included in commercial EVs. In fact Chris was one of those graduate students, and is now carrying on the work after Prof. Frank retired. This group launched Efficient Drivetrains, Inc., in Dixon, to commercialize its innovations which was then acquired by Cummins in 2018 and moved to Fremont. Chris explained that with Prof. Frank’s departure, the intensity of work at UCD on electric vehicle innovation slowed, with no teams participating in the DOE advanced vehicle challenges for a while.

UC Davis members at the EcoCAR EV Challenge launch event in Washington D.C. Left to right: MAE Ph.D. student Mohammad Abtahi, CS Associate Professor of Teaching Chris Nitta, PH&EV Program Manager Dahlia Garas. (Photo: U.S. Department of Energy)

But all that has changed and once again UCD will field a strong team in the latest EcoCar Challenge. Details are not known yet, but according to the website all 15 university teams will be provided a 2023 all-electric Cadillac LYRIQ – which they have four years to demonstrate the potential of advanced propulsion systems, connected and automated vehicle (CAV) technologies, and other innovative technologies to analyze energy efficiency. EcoCAR teams will utilize a combination of on-board sensors and bidirectional vehicle-to-everything (V2X) connectivity to implement energy efficient and customer-pleasing automated control features. Teams also will refine advanced powertrain along with charging and thermal systems to use grid electricity intelligently.

Mark Doerfer, COO of PEM Motion USA (headquartered here in Sacramento) talked about what they are looking to do to help those that want to design new unique EVs, to ramp up manufacturing processes, to help on innovation ecosystems across the globe, and to advance the state of the technology in battery manufacturing and recycling. Mark noted that they now have operations in the manufacturing hub of San Luis Potosi in Mexico, in the US Midwest, and in Orange County, CA. He said they view the importance of being in Sacramento as being close to the forefront of where new policies will be created that will drive innovation in EVs. He also mentioned their interest in software for autonomous driven vehicles.

After the presentations, we had an interesting panel discussion on what the future may hold for EV innovation. All three saw a revolution in vehicle ownership enabled by the rise of reliable autonomous driving software. People could change their minds about owning multiple vehicles if a car could be called up on demand if a primary vehicle is not available or not suited to the task. Even long distance trips might be handled better at high speed on dedicated highway lanes with autonomous vehicles that could “platoon” or travel in compact “bunches”, lowering drag from air resistance. They also noted that the existing vehicle population is poorly used. Most sit parked, most of the time. That’s a lot of ownership expense, especially when one rolls in annual taxes and insurance.

A second topic was how the charging system may evolve to handle the new EV population, with charging that is more under control of grid operators than individual car owners.

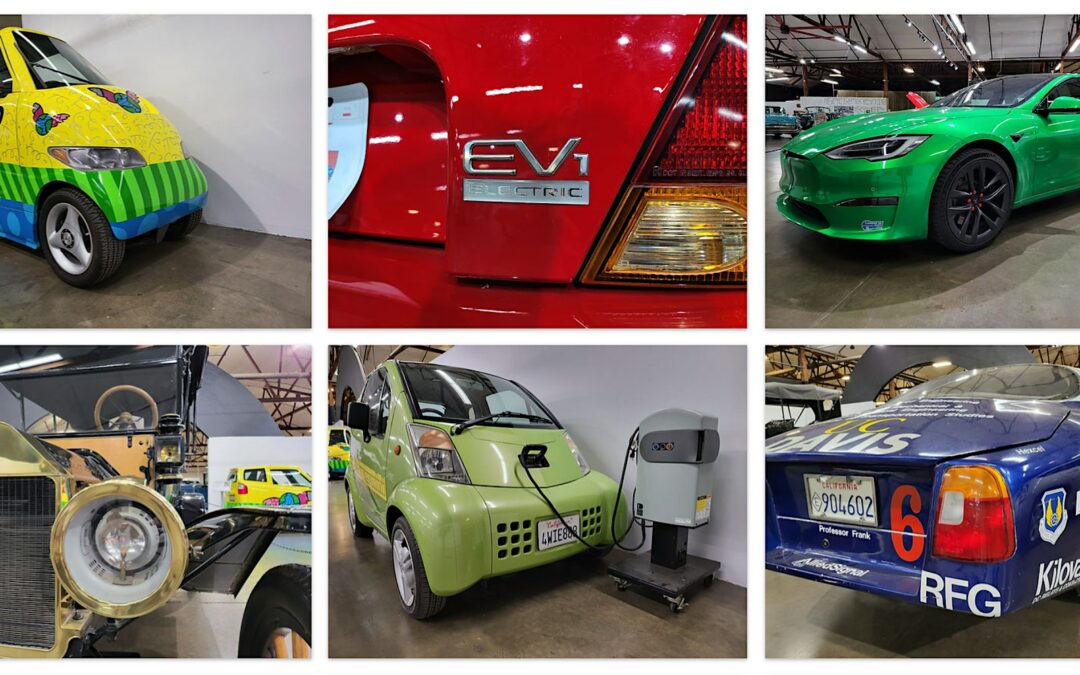

The session was recorded and is available here [LINK] if you are interested. Importantly we want to give a big thanks to the California Auto Museum which is one of those hidden gems in Sacramento. If you have never visited it, you should. The collection has been growing and right now there is a special exhibit on the evolution of electric vehicles. If you decide to go, be sure to use your GPS device. It is not the easiest location to find.