One of the flaws in the “hydrogen economy” argument is that it takes so much more energy to make “green” hydrogen through electrolysis than the hydrogen contains. That part of the equation may have changed with a new technology from Australian company Hysata that has been getting some serious funding. On top of an initial raise of about US$10 million, they added US$40 million in late 2022 and were granted $14 million in 2023 from a government fund for advancing hydrogen technologies. They are not close to having a commercial unit in the immediate future, but they continue to make progress.

Looking at hydrogen as a way to store electrical energy, the main question has been how much energy one gets back for a unit of energy input—the round-trip efficiency. The main competitor is a battery, which, in the best case, returns 85% of the energy it stores. The round trip in the case of hydrogen is a bit more complicated. There are losses along a long chain of steps, from using the electricity to split water to compressing and shipping the hydrogen to converting it back into electricity with a fuel cell. The sum of all the losses along this chain results in only 25–35% of the original energy input being returned. The two biggest losses are in the electrolysis step and the fuel cell step. The fuel cell step is usually about 60% efficient, with some hopes of pushing that to 65%. The electrolyzer step has been 55 to 75% efficient.

As a result, the impact of what Hysata has done is not likely to make a huge difference in the competition in the auto market between battery EVs and FCEVs but instead will make “green steel” and “green chemicals” replacing those derived from petroleum much more competitive. It will also have a big impact on the economics of making carbon-neutral fuels from recaptured carbon dioxide and water, which could be a game changer in creating “drop-in” net-zero carbon fuels to displace petroleum.

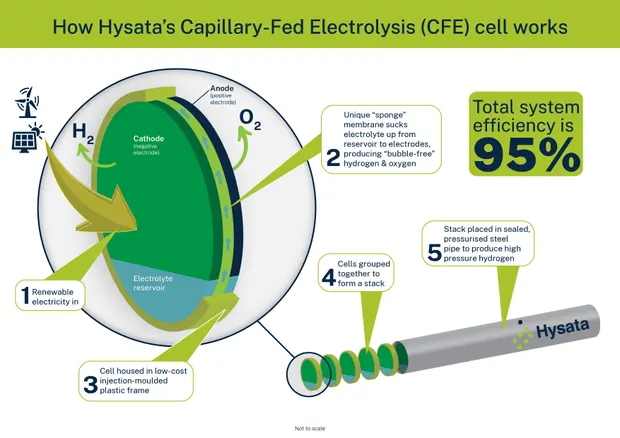

What Hysata’s new technology has done is push the electrolyzer efficiency above 90%, with the possibility that it could be as high as 95%. Said another way, electrolyzers have been taking 52.5 to 71 kWh to produce a kilogram of hydrogen from water, and that kilogram contains 39.4 kWh of energy. The Hysata technology could reduce the energy input to 41.5 kWh. Hysata has achieved this leap in efficiency by rethinking the whole setup for electrolysis. Instead of plunging electrodes into a bath of water, Hysata uses membranes to move tiny amounts of water up to the electrodes by capillary action. Apparently, eliminating the formation of bubbles at the electrodes markedly reduces the resistance in the electrolysis cell.

Be sure to join us to discuss alternate carbon-neutral fuels at our MeetUp on November 30. Save the date.

ABOUT THE AUTHOR

Gary Simon is the Chair of CleanStart’s Board. A seasoned energy executive and entrepreneur with 45 years of experience in business, government, and non-profits.

CleanStart Sponsors

Weintraub | Tobin, BlueTech Valley, Revrnt, River City Bank

Moss Adams, PowerSoft.biz, Greenberg Traurig, California Mobility Center