While broad electrification of the economy has emerged as a primary strategy for reducing CO2 emissions, there is another path that achieves the same result and it may be quicker to implement and less expensive. It could be a useful complement and addition to the electrification strategy, though. The two paths are not mutually exclusive.

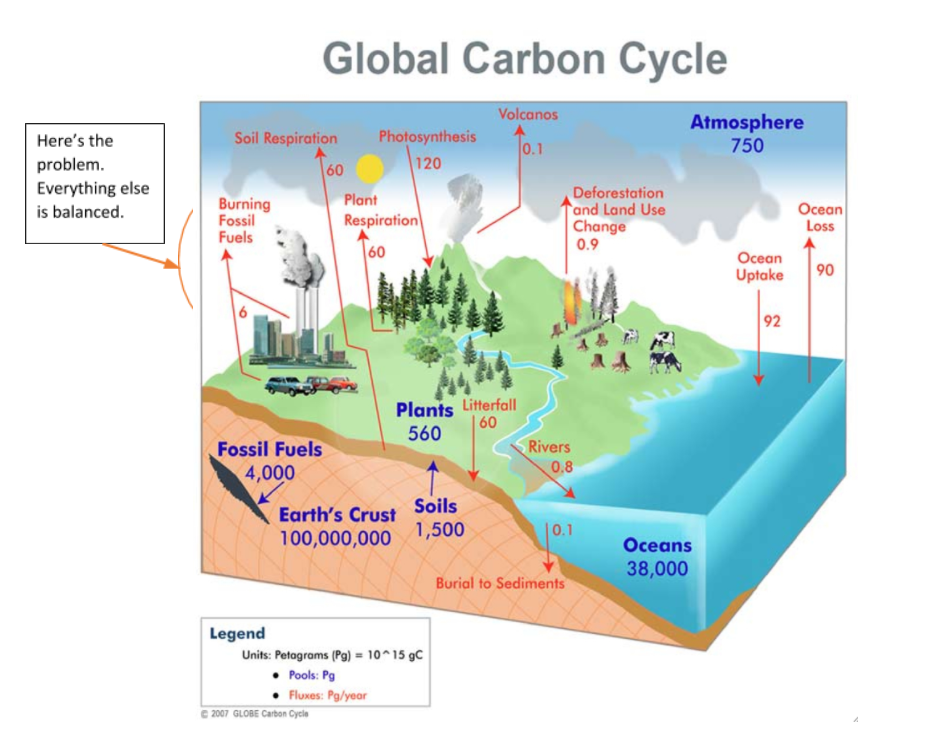

This second path involves recombining CO2 and water into liquid fuels that mostly look and behave like the fuels we have today. The difference is that they would not involve extracting fossil fuels and therefore would end the unbalancing of nature’s carbon cycle. That imbalance has led to the increase in atmospheric CO2 concentration from its historic level under 285 ppm to over 413 ppm today and on its way to exceeding 450 ppm. Putting CO2 in the air is itself not a problem. Every living thing does that. The problem is not recycling the same about back into organic or carbohydrate material simultaneously. That recycling to date has been done only by photosynthesis in plants. That is changing.

Until recently, the idea of recycling massive amounts of CO2 was considered fanciful. The usual response has been to assume one means growing some crop or using wastes and converting them into fuel. That path is fraught with all sorts of problems, not the least of which is the limitation on how much fuel could be produced that way. What is new is that there are many advances that indicate there could be an economical way to produce massive amounts of recycled carbon fuels in an industrial process that would not be as limited as biomass conversion. These advances are fertile ground for some entrepreneurs to take the innovations and make a new set of commercial products out of them.

There have been many new technologies created to do this industrial CO2 recycling. A list of articles talking about these advances are at the end of this blog. Some involve new catalysts. Some are done electrochemically with new membranes. There appears to be an increasing number of potential breakthroughs. But what is missing is the proof that these breakthroughs can lead to an economical process. And part of the proof is that CO2 can be captured and concentrated economically. One company is trying to do that by capturing CO2 directly out of the air. Others are focusing on already-concentrated CO2 sources like industrial exhausts.

The products that can be made include methane (the main component of natural gas), methanol (which is a fuel but also a major industrial chemical with 75 million tons per year now made from converting fossil fuels), clean propane, clean gasoline, clean diesel, and a variety of other industrial chemicals and fuel additives. Local company Greyrock Energy is a pioneer in this conversion process and is installing its initial plants right now. Those plants are using natural gas otherwise wasted as a feedstock, but the company’s vision from the start was to create renewable fuels from biomass or other captured CO2. Using waste gas has just been a low-hurdle way to get their conversion process commercialized.

There are many attractions to having recycled fuels available. One is the ease of introduction. Since they are virtually identical to conventional fuels, they can be introduced gradually into the current fuel streams, with no need for any equipment changes. There could be requirements for ever-greater proportions of recycled fuels in the total fuel pool just the way the renewable portfolio standards gradually hiked the fraction of renewable electricity in the total mix of power sources. That is already happening to a degree as CARB has acknowledged “Renewable Natural Gas” as a low-carbon source for meeting the state’s Low Carbon Fuel Standard. The CPUC also has set up accounting mechanisms and standards for users to acquire Renewable Natural Gas and have it delivered to them through the existing gas pipelines. So these recycled carbon fuels are already being gradually introduced into the conventional fuel streams.

Second, substituting recycled carbon fuels are a way to reduce the use of fossil fuels in the existing stock of buildings, vehicles, and industries, rather than trying to replace that equipment. Doing so would probably take away some of the user anxiety over decarbonization, and make it easier to achieve. Owners of cars with standard internal combustion engines could then become part of the climate solution rather than part of the problem.

Third, the existing fuel delivery infrastructure of pipelines, filling stations, and distribution networks would not need to be abandoned, avoiding the need for massive investment in some new replacement infrastructure.

Electrification is clearly a great way to decarbonize buildings and vehicles. It brings other benefits such as improvements in indoor air quality from switch gas ranges for electric induction models. But electrification tends to focus on new purchases—of homes, of vehicles, and of buildings. Recycled carbon fuels are another decarbonization strategy and do well in decarbonizing existing energy-using equipment. By no means is the recycling of CO2 back into fuels a proven commercial reality, but advances continue to move in that direction. The fact that it is a relatively unnoticed idea means there is lots of room for entrepreneurial innovation. The field is not crowded. Someone may make a ton of money off of it. How about you?

Recycled Carbon Fuels Reference List

https://news.stanford.edu/2019/10/17/new-catalyst-helps-turn-carbon-dioxide-fuel/

https://www.motortrend.com/news/direct-co2-to-fuel-conversion-technologue/

https://www.anl.gov/article/a-new-leaf-scientists-turn-carbon-dioxide-back-into-fuel

https://scitechdaily.com/new-electrocatalyst-turns-carbon-dioxide-into-liquid-fuel/

https://www.chemistryworld.com/news/zeolite-catalysts-convert-carbon-dioxide-to-fuel/3007572.article

https://blog.nextias.com/hydrogen-compressed-natural-gas-h-cng

https://www.theengineer.co.uk/hydrogen-enriched-natural-gas/

ABOUT THE AUTHOR

Gary Simon is the Chair of CleanStarts Board. A seasoned energy executive and entrepreneur with 45 years of experience in business, government, and non-profits.

CleanStart Sponsors

Weintraub | Tobin, EY, BlueTech Valley, Revrnt, Moss Adams, PowerSoft.biz

Momentum, College of Engineering & Computer Science at Sacramento State