Patience, persistence, and optimism are paying off. Wind Harvest has managed to get to Technology Readiness Level (TRL) 7 with its vertical axis wind turbine (VAWT) technology. That means that they have tested a full-scale prototype in commercial conditions. That testing was done at a UL Advanced Wind Turbine Testing Facility in North Texas where the near-ground winds are very turbulent, just the sort of challenging conditions the Wind Harvester are designed to exploit.

The prototype provided the data to validate the company’s proprietary “aeroelastic” engineering models that originally were developed by Sandia National Labs. In the process, the company engineering team was able to do a serious redesign—which has dropped the manufacturing and installation costs and increased the durability of the blades, mast, and struts. It also led them to patent a number of critical new parts, patents which themselves may be of great value.

Now they are getting ready for full third-party certification of their new unit in a longer test at that same facility. That will advance them through TRL 8. They hope to get that started by the middle of the year. Then the next challenge is financing ten or more turbines in different demonstration projects to collect 1-2 years of performance data that banks need to provide project loans to their customers’ wind farm projects. They need $10 million in new investment to get all this done. They are just as clever in raising money as they have been in continuously improving their engineering designs.

There is a lot to learn from their experience. CEO Kevin Wolf has been officially a part of the company for nearly 25 years, building on work that was started by others in the 1980s. That is a testament to persistence, patience, and optimism about solving the next problem. But Kevin is convinced it will all be worthwhile. He sees the potential for installing hundreds of thousands of MW of vertical axis wind turbines that use their existing and future patents.

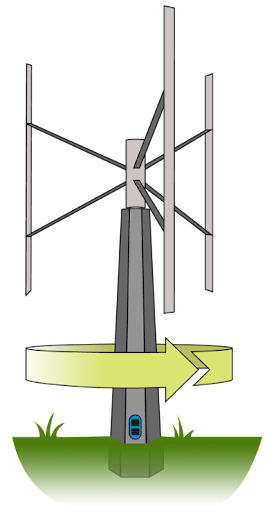

Wind Harvester Model 4.0

50-75 kW rated electrical power

25 mph rated wind speed

11 mph cut-in/56 mph cut-out wind speeds

122 – 310 MWh of Annual Energy Production

Rotor Height: 13 meters

Rotor Diameter: 13 meters

Swept area: 169 m2

3 Blades/ 6 arms

Base tower height: 8–20 meters

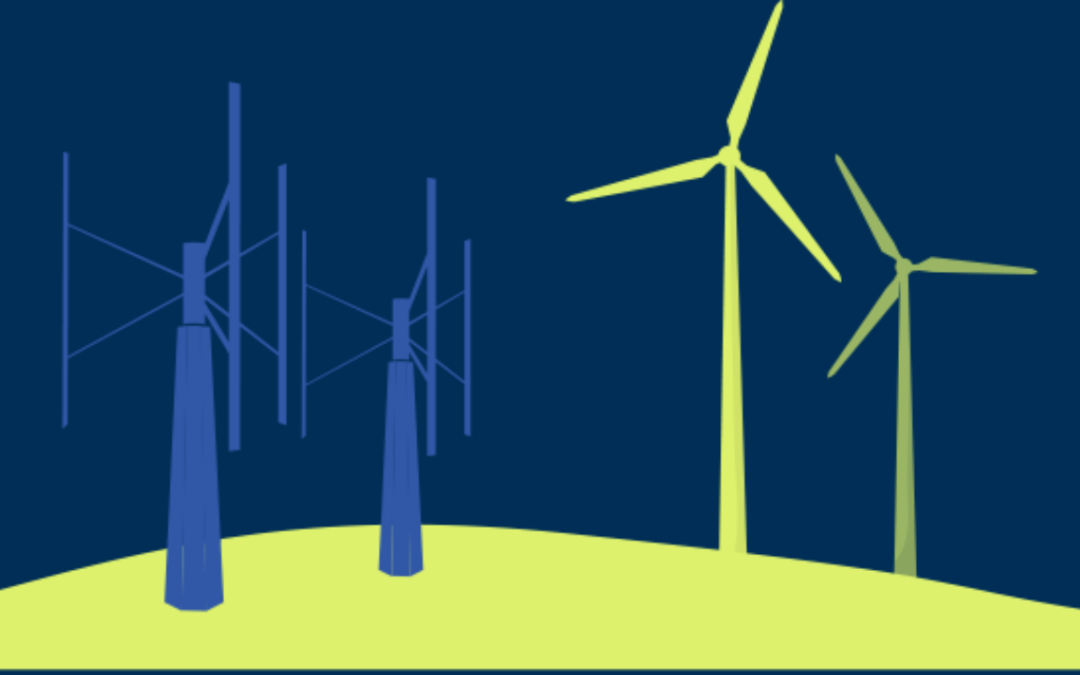

You may recall that Wind Harvest is pursuing a small 50-75 kW wind turbine that can handle the turbulent winds near ground level—a resource which the company has documented has huge potential—and installing thousands of them. The idea is to install these short turbines, tightly spaced (3’ apart) under and between the big horizontal axis wind turbines already in wind farms in California and around the globe. The idea is to be able to harvest more of the world’s best

wind resources and reduce the need to convert more land into wind farms. When existing wind farms add short VAWTs to increase their capacity factors, new transmission lines are not needed to move the extra energy to the grid.

The company was very fortunate in having some patient early investors who put in over $16 million to move the company forward. However, getting the next ten million is going to require some clever ideas. Kevin talked to over 100 VCs in the last few years and has become convinced that they were not going to be a source of investment until his machines were fully tested, validated and bankable. There have been too many failed investments in past clean energy technology companies that were not well vetted That is why he has been so focused on getting past TRL 8 and 9.

Kevin and the company have found some interesting ways to use crowdfunding to generate money for the testing and redesign steps, but this is only a small amount at a time. He has just closed a round and is about to launch another one via netcapital.com to secure the money to complete TRL 8 and have a turbine ready for sale. Then he wants to raise much more to develop the pioneer demonstration projects to get the company into revenue and the proof points for TRL 9. Facing skeptics still among the big wind farms, his likely locations for this first project may be military bases, islands, and special situations where fear of impacts on the tall turbines will not be such an obstacle.

His longer-term vision is not to be a project developer, but rather for Wind Harvest to license their patents to bigger players and collect royalties. However, to get to that point, the company likely needs to do more project development itself. Fortunately, the payment of tax credits upfront provided in the IRA, coupled with accelerated depreciation means that there should be a pool of investment available from those with a big tax bill they want to offset, getting them over the hurdle of the high cost of initial units.

Over time, the company sees the price dropping rapidly with volume. The units are made of simple, mass-producible components that can be delivered in kit form. The fully installed costs for small 1-2 MW-scale projects should be less than $3500/kW, with prospects to drop that cost another 40% with time and volume.

Kevin’s parting words were “This has been a longer, more difficult slog than we ever thought.” Many cleantech startups can say the same. But in the case of Wind Harvest, the team never gave up and found ways to keep going and actually benefit from the setbacks. He notes, “What we learned has resulted in a breakthrough technology to make use of a massive, untapped renewable energy resource”.