Highlands Power Making Waves in Clean Mobility

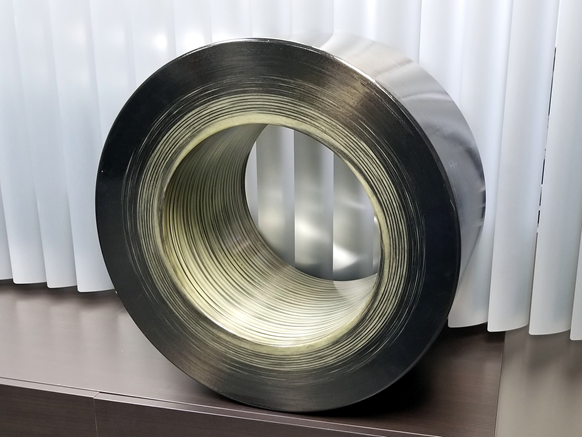

What is the most delicious electric motor in the world? It could be the “pancake”. Also known as the Axial Flux Motor, it is considered the most efficient and powerful types of electric motor, but also one of the hardest to successfully build. Building an axial flux motor that is incredibly powerful as well as easily manufactured is a tall order, but Highlands Power is looking to develop just such a motor here in Sacramento.

The Axial Flux Motor Highlands is looking to produce is different from the traditional Radial flux motor in that the Magnetic Flux travels parallel to the axis of rotation as opposed to out from the center. What does that mean for the the measurables of the motor? It means much less weight and a more compact motor (“flat as a pancake”) compared to the much heavier conventional motor. It also means more efficiency and in electric transportation, efficiency is king.

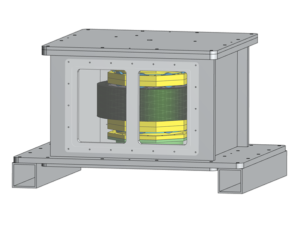

There is nothing particularly new about the idea of an axial flux, pancake motor. What Highlands has done is to make one out of lightweight materials that can deliver surprisingly high torque, eliminating the need for a gearbox. Called the S-ONE, Highlands’ motor delivers a much better torque-to-weight ratio than current production motors. In addition, the motor is stackable, meaning if more power is needed units can be ganged together to generate as much power and torque as the vehicle needs. It is designed to be relatively low cost as well. This versatility is the cornerstone of Highlands’ plan and believes it is the key to developing more affordable electric vehicles.

The S-ONE uses an entirely new new motor layout, cooling system and manufacturing process to produce 3-4x the torque of current drivetrain motors without increasing size, weight or cost. All this performance is held in an all-composite, shock resistant housing that helps the S-ONE withstand the toughest environments on and off road. These advancements in motor technology can significantly reduce the cost of an electric vehicle and make EVs more accessible to mass market consumers.

Conner Whaley, CTO of Highlands has been aggressively pursuing building this motor for the past several years. Now, Highlands is refining the S-ONE to be ready for production and scale in the near future. At this point, more than ten automotive suppliers and OEMs are awaiting one of the 25 third-generation prototype motors to be built by Highlands for benchtop and in-vehicle testing. We look forward to hearing more as they grow and push the electiric transportation revolution forward.

ABOUT THE AUTHOR

Thomas is the Executive Director of CleanStart. Thomas has a strong background in supporting small businesses, leadership, financial management and is proficient in working with nonprofits. He has a BS in Finance and a BA in Economics from California State University, Chico. Thomas has a passion for sustainability and a commitment to supporting non-profits in the region.

Sponsors

Weintraub | Tobin, Revrnt, Moss Adams, PowerSoft.biz, Greenberg Traurig