Sometimes you just have to see a technology to “get it”. That’s what happened when we made the journey to the backwoods of El Dorado County to see what CR Flight was doing at its development shop. The article we published on them in April of 2021, based on an interview, has consistently been among the top 5 most-read articles we have ever done. It racks up substantial new views every month. We wanted to find out why.

The answer is that CR Flight has done something pretty remarkable, which you cannot appreciate properly until you see it in operation. Clearly, they have impressed some substantial motor manufacturers with their demos at trade shows because they now have some of them very eager to get their hands on the technology.

The answer is that CR Flight has done something pretty remarkable, which you cannot appreciate properly until you see it in operation. Clearly, they have impressed some substantial motor manufacturers with their demos at trade shows because they now have some of them very eager to get their hands on the technology.

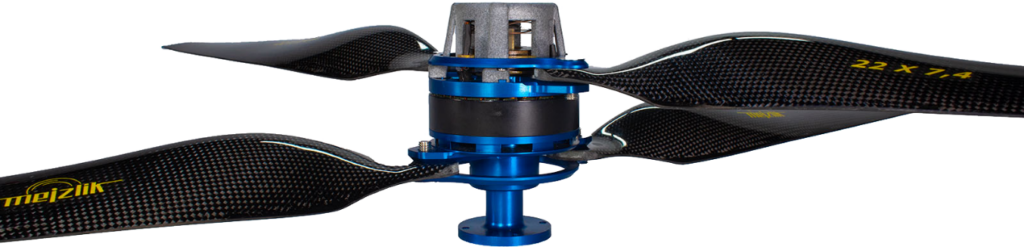

In a nutshell, here is what the CR Flight team has done: In a standard electric motor, you bolt the shaft down, and the outside spins. That spinning part is the rotor, and it is an outside cover with permanent magnets. The inside part has all the coils and wires and it is called the stator. It doesn’t move. However, a lot of force is exerted on the mount to try to turn it in the opposite direction from the rotor. Newton’s Third Law and all that.

CR Flight’s out-of-the-box idea is to let them both spin and put a propeller on both the rotor and the stator. In this configuration, the stator is now an armature and is no longer static. A lot more thrust can be delivered from the same motor with less electricity being used. In fact, by actual measurement, 27 to 47% more thrust is needed because that sounds like magic; you have to see it to believe it. No laws of physics are violated. It just takes some clever engineering, which is now fully patented, to make it work. And a willingness to ignore people who said it was impossible.

What that added thrust means is drones that can deliver much larger packages, electric airplanes that are lighter and can go much farther on a single charge, and motors that can last much longer because they are running cooler as the armature is now spinning and sucking air through the motor.

The additional benefit of the counter-rotating props is that they cancel out the torque of the single propeller and the wasteful spill of energy, creating a spinning cone of air that provides lift. The energy now all goes into downforce. In the usual way of creating counter-rotating props, a complicated shaft-within-a-shaft design, and some gears are needed, all of which add a lot of weight. In the CR Flight approach, it is just some parts that bolt on either side of the motor case itself.

For a manufacturer of electric motors, the great advantage of CR Flight’s innovation is that it does not require any changes to the internals of the motor. Just modifications added outside of the motor housing.

For the past two years, CR Flight has been gathering data and documenting each of its claims. It has some enthusiastic followers now that have become believers, including one of the manufacturers of popular axial-flux electric motors for aircraft. It seems to be just the right innovation for these times when drones and electric passenger aircraft are looking for ways to squeeze out more range and carry heavier loads. These are not incremental improvements made by CR Flight, these are breakthrough-scale improvements that could be the key to getting the whole electric aircraft industry off the ground, pun intended.

The team is looking at other applications for its invention. The most obvious is to employ the same insight into electric drive motors for watercraft. Early test results show just about the same dramatic improvements in performance.

Their next step is to manufacture a small volume of products on behalf of interested manufacturers to get them hooked on the technology. Then they want to license several manufacturers to employ their innovation in particular markets.

Keep an eye on these guys.

ABOUT THE AUTHOR

Thomas is the Executive Director of CleanStart. Thomas has a strong background in supporting small businesses, leadership, financial management and is proficient in working with nonprofits. He has a BS in Finance and a BA in Economics from California State University, Chico. Thomas has a passion for sustainability and a commitment to supporting non-profits in the region.

Sponsors

Weintraub | Tobin, Revrnt, Moss Adams, PowerSoft.biz, Greenberg Traurig