Wind Harvest International Eyes Potential for Small Turbines

There has been an acceleration in the adoption of renewable energy, especially wind power. As wind energy has demonstrated a solid return on large projects, there is the opportunity for novel applications to be applied to unique situations. Like all technologies, innovation in Wind Power is increasing its versatility and potential applications. Kevin Wolf, co-founder of Wind Harvest International, is using his novel wind turbines to take advantage of new opportunities.

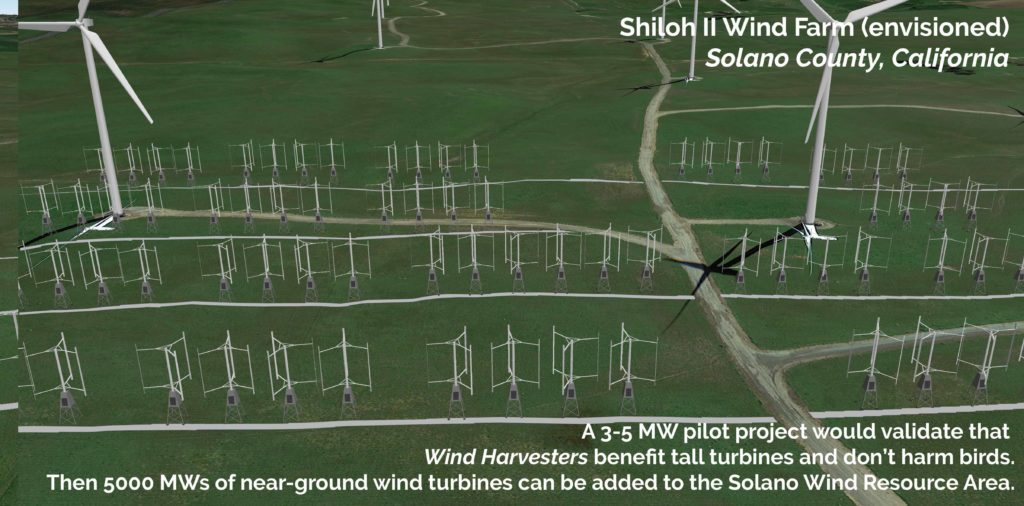

Currently, Wind Harvest is working to better capture wind energy. Wind power has been having a renaissance in the US. But there is the underutilized wind that Kevin Wolf thinks their turbines can capture. The wind closest to the ground. Typical turbines can’t use this resource because the wind near the ground is too turbulent, but Wind Harvest has developed a solution that looks like it could work. By using H-type turbines with two connections per vertically aligned blade rows of these can be installed under the tall turbines. There they can leverage economies of scale and existing land, roads, and infrastructure with large project developments. In the process, this gives the wind farm owner and the rancher who lease their land to increase income from their windy properties.

Wind Harvest’s technology makes use of the coupled vortex effect; when arranged in close proximity to one another, a pair of H-type wind turbines create a synergistic effect. They anticipate this will increase wind speeds through the rotors. They anticipate their compact turbines having the ability to produce electricity at night because in most wind farms in places like California, the wind blows all night long many nights of the year. When installed in existing wind farms, especially with batteries, Wind Harvester turbines aim to increase energy capacity to meet demand that would be provided by gas peaker plants and fossil fuels. They can be built and maintained a lot easier. This means they can create jobs in the local community, both in their manufacturing and maintenance.

If you want to learn more or get involved, check them out and see their fundraiser on WeFunder.

Wind Harvest International will also be presenting at our Spotlight Investor Night on November 12th.

ABOUT THE AUTHOR

Osato Evbuomwan is a CSU Sacramento Mechanical Engineering Graduate Student who is the newest associate at CleanStart. Growing up in Nigeria with smog from backup diesel/ gasoline generators inspired Osato to work towards building a sustainable future for the world.

CleanStart Sponsors

Weintraub | Tobin, EY, Stoel Rives, Revrnt, Hacker Lab

BlueTech Valley, Buchalter, Moss Adams, PowerSoft.biz

College of Engineering & Computer Science at Sacramento State