Added Insights From 2022 Progress Report

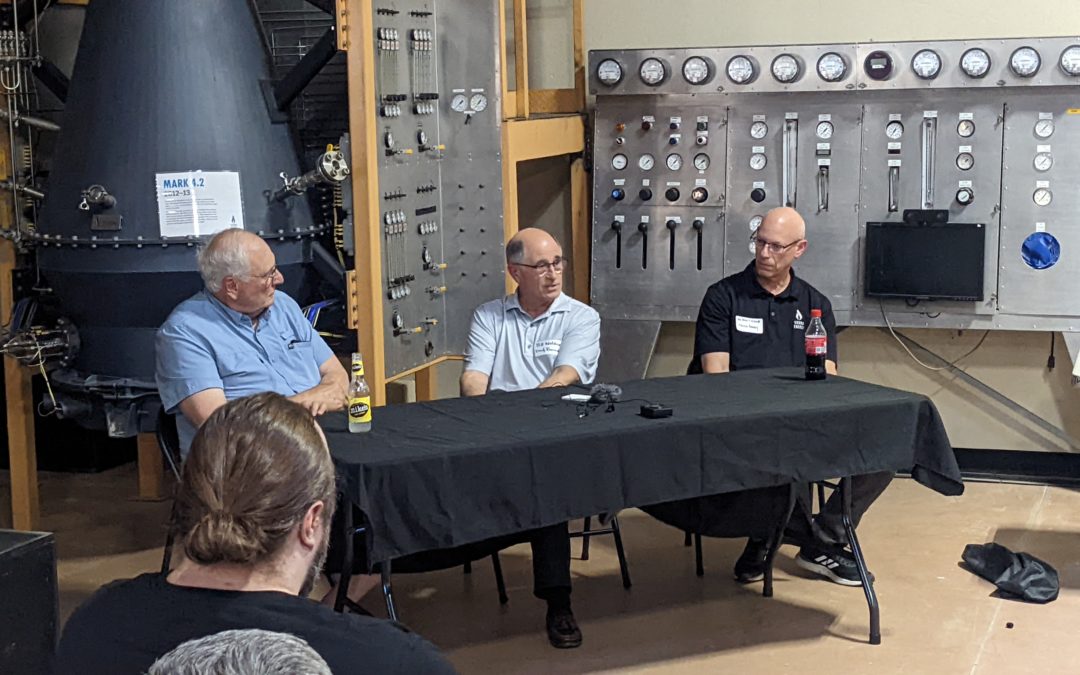

In response to requests for more discussion on the results of our latest survey of the regional core clean tech cluster, we held a Zoom call on June 23. Here are some of the points we covered:

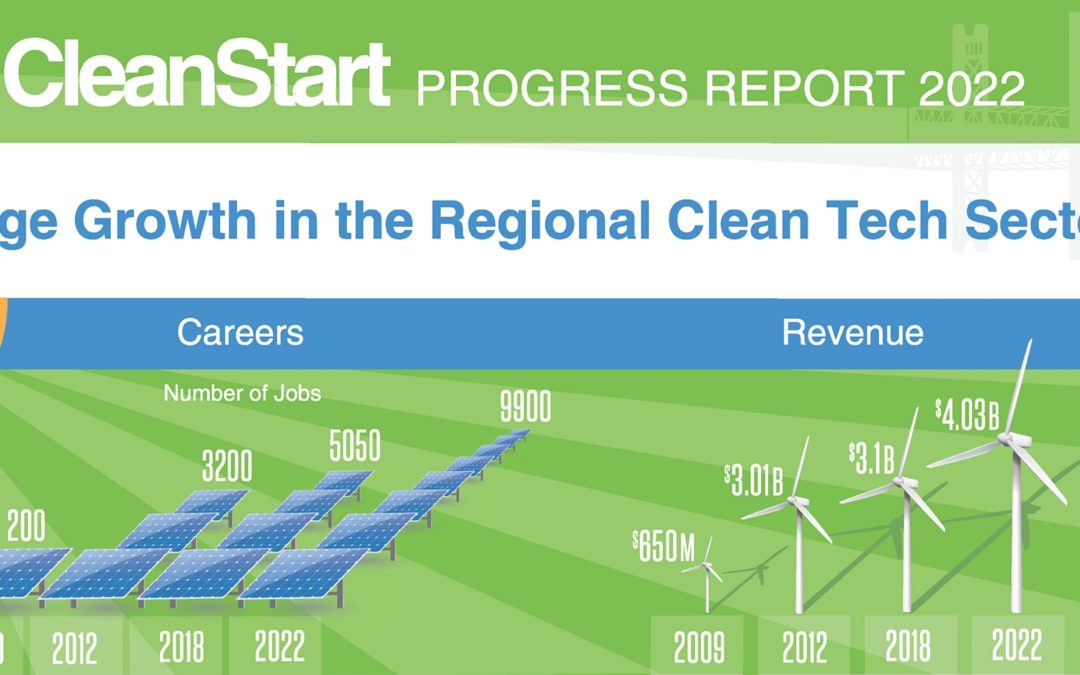

- The increase in jobs and opportunities here is making the area much more for recruiting talent. People see this as a good place to develop a career with good chances to move among growing companies.

- We haven’t yet seen a big exit that creates multiple millionaires. That will likely take more companies reaching the point where they go public to tap larger sources of capital.

- We probably won’t see a doubling in jobs in the sector in the next two years like we just did. Revenue however should grow more than 25% over this period.

- The biggest sources of growth were in mobility, conversion of wastes and biomass, and building efficiency.

- We have companies in the core cluster all along the “Maturity Chain”. It is not dominated by early-stage companies struggling to get a foothold. That’s a big step up.

- Other reports have indicated much higher numbers of jobs in the local “clean economy”–like 40,000+. Why are our number so much smaller? The major studies we have seen count government jobs in environmental agencies. We look only at businesses, and of those, only businesses whose products have a significant IP component. We don’t count businesses which are solely selling other people’s products like solar installers. It is the IP-based companies which we see as “engines of growth” and pay close attention to them.

We also gathered some important new information from those that were on the call:

- Infinium will also expand in West Sacramento by adding a technology R&D center, to improve its offerings continuously. This will involve adding significant high-tech jobs and will likely bring some from overseas talent to the area.

- Judy Nottoli of CARB noted that there is an unprecendented amount of funding becoming available in the next year to support projects on Low Carbon Fuels, conversion of forestry wastes, and caron reduction. She pointed to upcoming modifications to the LCFS rules next year and the availability of funding from the iBank’s Climate Catalyst Fund that people should have on their radar.

There was much more to the discussion and if you are interested you can watch the recording of the entire 36-minute session

ABOUT THE AUTHOR

Gary Simon is the Chair of CleanStart’s Board. A seasoned energy executive and entrepreneur with 45 years of experience in business, government, and non-profits.

CleanStart Sponsors

Weintraub | Tobin, BlueTech Valley, Revrnt,

Moss Adams, PowerSoft.biz, Greenberg Traurig